Core Functionality: How Engine Mounts Ensure System Integrity and Safety

Vibration Dampening and Resonance Control Across Operational RPM Ranges

Engine mounts work by soaking up those annoying vibrations from combustion, so they don't get passed along to the car's frame. These components are built to handle frequency ranges from around 5 to 200 Hz, which covers most of what happens inside both gas and diesel engines. According to some recent noise vibration harshness research published last year by Hutchinson, this isolation can cut down on cabin noise by more than 80%. The newer rubber hydraulic composite designs actually adjust themselves based on engine speed. They're especially good at dampening vibrations when the engine is running between roughly 2500 and 3800 RPM, where things tend to get really bumpy if left unchecked. Without proper control, these vibrations might actually become three times stronger than normal. Keeping them in check helps maintain accurate sensor readings and stops electronics from wearing out too quickly.

Dynamic Load Management: Sustaining Structural Integrity Under Torque, Shock, and Thermal Cycling

When vehicles accelerate suddenly, engine mounts must handle torque changes over 400 Newton meters while keeping engine movement under control at just 3 millimeters maximum. The newer EPDM materials used in these mounts stay flexible even when temperatures swing from minus 40 degrees Celsius all the way up to 120 degrees Celsius. This helps them avoid getting stiff or developing cracks that regular rubber tends to get after repeated use. Testing shows that after going through about 50 thousand temperature cycles, these improved mounts still hold around 93 percent of their initial strength, which means they significantly reduce problems such as cracked exhaust manifolds and misaligned subframes. Another benefit comes from hydraulic chambers built into the design, which spread out impact forces better than standard setups. This actually cuts down on peak stress points within the structure by almost half according to research published in SAE Technical Paper 2021-01-0325.

Bulk Procurement Risks: Why Consistency and Compliance Define Engine Mount Reliability

IATF 16949 Certification as the Baseline for Tier-1 Supplier Qualification

IATF 16949 certification is the non-negotiable benchmark for tier-1 engine mount suppliers, enforcing automotive-specific protocols for defect prevention, process control, and continuous improvement. Its adoption directly correlates with reliability: certified suppliers demonstrate 40% fewer field failures in industry audits (2023), significantly reducing recall exposure and warranty liability.

Dimensional Repeatability (±0.3mm) and Statistical Process Control at Scale

Consistent geometry is essential for seamless powertrain integration. Achieving ±0.3mm tolerance across bulk production requires rigorous Statistical Process Control (SPC) of variables like mold pressure and curing temperature. Suppliers lacking SPC exhibit 15% higher dimensional drift—triggering NVH complaints and costly assembly-line stoppages.

| Risk Factor | Certified Suppliers | Non-Certified Suppliers |

|---|---|---|

| Defect Rate | ≤0.1% | ≥2.3% |

| Dimensional Accuracy | 99.8% compliance | 84% compliance |

| Warranty Claims | 3x lower | Industry average |

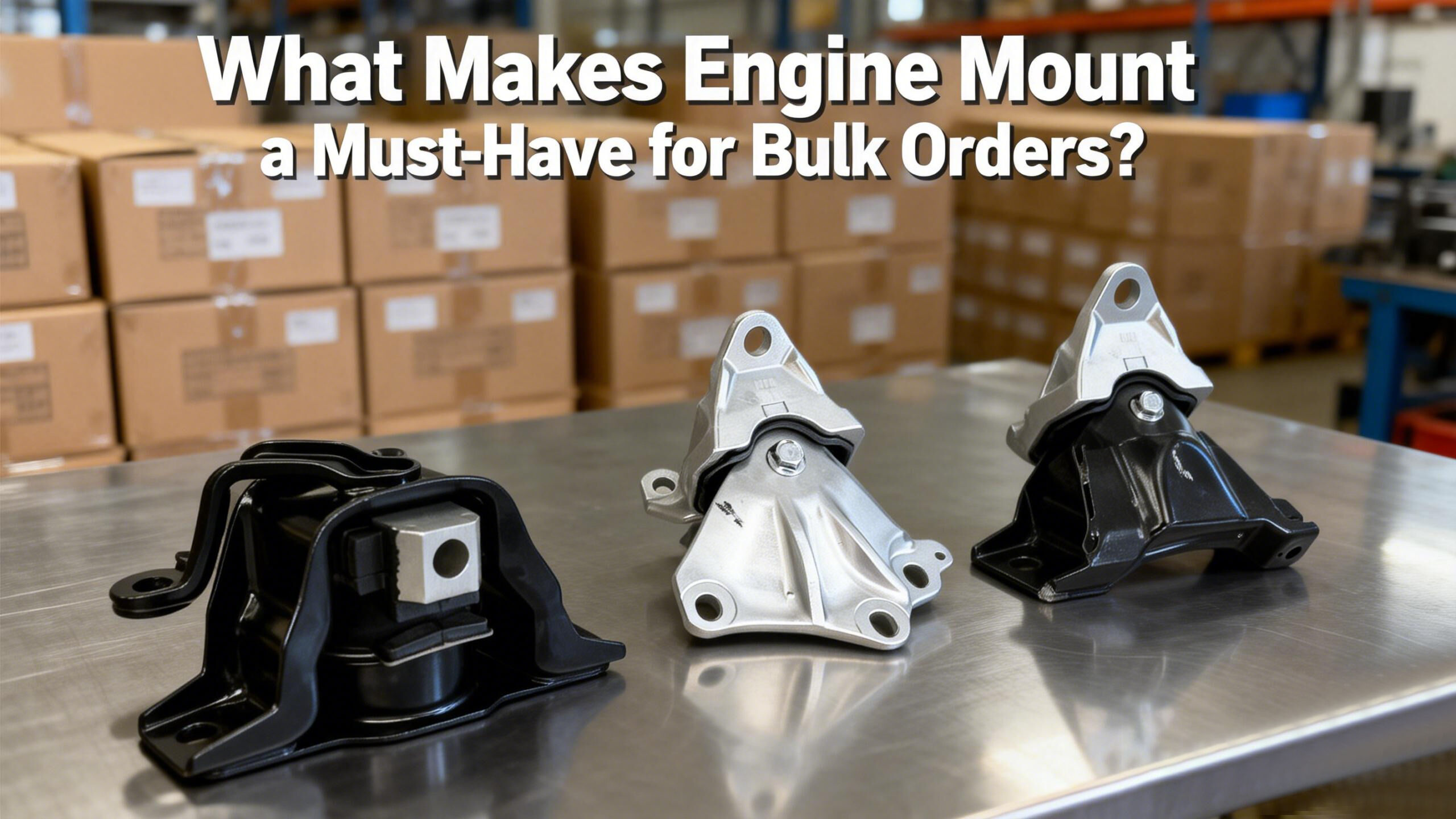

Material Science in Practice: Matching Engine Mount Composition to Powertrain Type

Rubber, EPDM, and Hydraulic/Hybrid Designs for ICE, EV, and Commercial Vehicle Applications

Material selection must align precisely with powertrain dynamics. Internal Combustion Engines (ICE) generate intense low-frequency vibrations—up to 80% below 200 Hz—requiring oil-resistant, heat-tolerant rubber compounds capable of enduring sustained 120°C+ under-hood temperatures. EPDM mounts extend that resilience across —40°C to 150°C, maintaining elasticity where standard rubber degrades.

Compared to traditional vehicles, electric cars generate a different kind of noise problem. They make high frequency sounds around 2 to 5 kilohertz because of how quickly they deliver torque. The solution? Hydraulic or hybrid mounts that combine fluid damping with rubber parts work about 30 percent better at reducing these noises than regular solid mounts do. For big commercial trucks that need to last forever, manufacturers use special multi chamber hydraulic systems attached to strong steel frames. These setups hold up against massive shocks when cargo moves around, surviving forces over 10,000 Newton meters. No matter what type of vehicle we're talking about though, picking the right materials makes all the difference for controlling noise levels and making sure components don't wear out too fast.

Total Cost of Ownership: How Bulk Engine Mount Quality Reduces Warranty, Rework, and Line-Down Costs

When companies buy high quality engine mounts in large quantities, they typically see a good return on investment because these mounts tackle three big money issues. For starters, they help reduce warranty claims by around 40 to maybe even 60 percent since they last longer and perform consistently under all kinds of conditions. This means fewer replacements need to be handled and less paperwork for administrators. The second benefit comes from how stable these mounts stay dimensionally within about plus or minus 0.3 millimeters. That kind of precision cuts down on assembly problems where parts just don't fit right, so workers spend less time making adjustments and fixing things during production. And third, which is probably the most important point, these mounts stop serious powertrain misalignments that can bring entire assembly lines to a grinding halt. We're talking about real money here too - every single minute that a plant stops operating due to such issues costs roughly $740,000 according to industry standards. Premium mounts also protect against vibration damage throughout various components including sensors, exhaust systems, and electronic parts, keeping operations running smoothly while reducing overall maintenance needs over time.

FAQ Section

What is the primary function of engine mounts?

Engine mounts are designed to absorb vibrations from the engine, preventing them from being transmitted to the car's frame and cabin, thus ensuring system integrity and reducing noise.

Why is IATF 16949 certification important for engine mount suppliers?

IATF 16949 certification ensures that suppliers follow automotive-specific protocols for defect prevention, process control, and continuous improvement, resulting in higher reliability and fewer warranty claims.

How do material choices affect engine mount performance?

The choice of materials such as rubber, EPDM, and hydraulic components is vital for aligning mount performance with the powertrain's dynamics, ensuring durability and reducing noise.

What are the benefits of using high-quality engine mounts in bulk?

Using premium engine mounts reduces warranty claims, minimizes assembly issues, and prevents costly line stoppages due to misalignments, providing a significant return on investment.

Table of Contents

- Core Functionality: How Engine Mounts Ensure System Integrity and Safety

- Bulk Procurement Risks: Why Consistency and Compliance Define Engine Mount Reliability

- Material Science in Practice: Matching Engine Mount Composition to Powertrain Type

- Total Cost of Ownership: How Bulk Engine Mount Quality Reduces Warranty, Rework, and Line-Down Costs

- FAQ Section