Copper-Brass Car Radiators: Proven Longevity and Thermal Performance

Why High Thermal Conductivity and Corrosion Resistance Matter for Car Radiator Durability

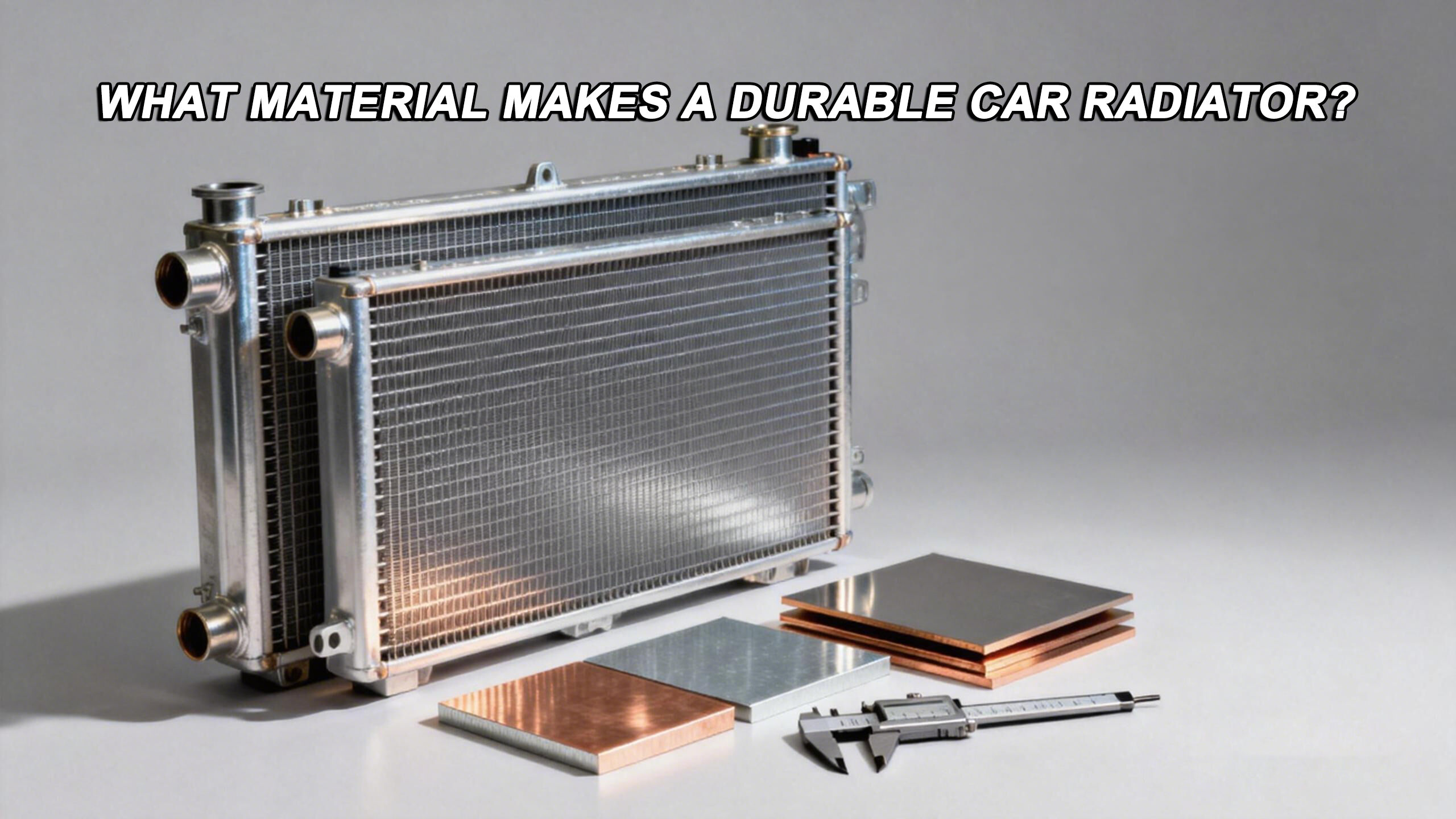

Car radiators made from copper-brass are really good at conducting heat, about double what aluminum can manage. This means engines cool down faster and stay cooler during long drives, which cuts down on the chance of overheating problems. What makes them last longer is their ability to resist corrosion. The metal itself stays stable over time, plus it forms a kind of protective layer when it comes into contact with water and coolant. This layer slows down rusting without weakening the radiator's structure. Another big plus? Copper-brass doesn't break down when used alongside other metals in cooling systems, something aluminum struggles with. Even as coolant gets older, copper-brass stands up to electrolytic damage better than most materials. Real world testing across vehicle fleets has found that these characteristics cut down on solder joint failures by around 80 percent versus aluminum radiators. That translates to much longer service life before replacement becomes necessary.

Real-World Evidence: Fleet Data Showing 12–15-Year Lifespan in Low-Corrosion Conditions

Fleets running in areas with mild weather and low humidity often see their copper-brass radiators last between 12 to 15 years with hardly any maintenance needed. One big logistics company actually reported that nearly all their radiators (around 9 out of 10) made it past half a million miles without needing repairs, and they pointed to brass being able to handle temperature changes better as the reason. When trucks use coolants that aren't full of minerals and have the right additives, these copper-brass systems leak from corrosion about three times less often compared to similar aluminum setups. The downside is they weigh more - roughly 15 to 25 kilograms extra per radiator - but most operators find that the longer lifespan makes up for this extra weight, especially on those long haul routes where replacing parts costs so much money in downtime and labor.

Aluminum Car Radiators: Lightweight Efficiency vs. Long-Term Durability Trade-Offs

How Heat Cycling and Coolant Chemistry Accelerate Aluminum Core Degradation

Car radiators made from aluminum save weight compared to traditional copper-brass models, cutting down radiator mass around 40%. This lighter construction helps improve fuel economy too, giving about a 5 to 7 percent boost in efficiency. But there's a catch with all this weight saving. When aluminum radiators go through repeated heating and cooling cycles, something happens at the microscopic level inside the metal structure. After roughly five to seven years of regular driving, tiny cracks start forming in those delicate fin structures and tubing. Coolant chemistry matters just as much though. The standard ethylene glycol stuff we put in our cars tends to eat away at unprotected aluminum over time. And then there's the issue with silicate additives in some coolants that actually create abrasive deposits inside the system. Once coolant gets contaminated or starts breaking down, it can speed up internal wear by nearly two thirds, causing pits to form faster and making those thin walls between tubes get even thinner.

The Industry Shift Explained: Performance Gains Versus Erosion Vulnerability

Car manufacturers started using aluminum radiators mainly because they needed to comply with tough emissions regulations around the world. Each radiator cuts down on car weight somewhere between 15 to 25 kilograms, which helps automakers achieve their overall weight reduction goals for better fuel efficiency. But there's a catch. Aluminum reacts chemically in ways that make it prone to something called galvanic corrosion whenever it touches different metals like steel brackets used for mounting. This becomes a big problem in places where it's damp or salty air hangs around. Unlike copper-brass radiators, aluminum doesn't form that protective layer over time that helps prevent damage. Once those oxide layers get damaged, they stay damaged forever. That explains why we see so many failures in coastal areas or humid climates within just 6 to 8 years of installation. That's roughly half as long as similar copper-brass models last, even though aluminum starts off conducting heat much better initially.

Plastic-Aluminum Hybrid Car Radiators: Cost Savings at the Expense of Structural Integrity

Tank-to-Core Interface Failures: The Hidden Weak Point in Modern Car Radiator Design

Most original equipment manufacturers have turned to plastic-aluminum hybrid radiators because they save money and reduce weight. Nylon composite end tanks bring down manufacturing costs around 40%, while making the whole radiator lighter by roughly 30 to 40% compared to traditional metal versions. However, there's a problem with how these materials work together. Aluminum expands when heated at about 23 micrometers per meter per degree Celsius, but reinforced nylon expands much faster, somewhere between 70 to 90 micrometers under the same conditions. This difference creates stress at the bond where they meet every time the engine warms up or cools down. Over time, usually after five to seven years, tiny cracks start forming in the epoxy or adhesive that holds everything together. Industry studies show this leads to unexpected coolant leaks in about one out of four units. These failures don't show any warning signs like rust spots or visible damage, so mechanics often discover them only when the car starts overheating. Even though manufacturers try to fix things with better gasket designs and special additives in the coolant, the basic issue remains unsolved for budget-conscious applications where cost savings still outweigh long term reliability concerns.

Comparing Car Radiator Materials: A Practical Guide to Choosing for Maximum Lifespan

What kind of material goes into your car's radiator really affects how long it will last. The right choice comes down to what you need most from your vehicle, where you drive regularly, and what matters most in performance. Copper brass radiators tend to stick around longest, often giving 12 to 15 years of service in normal weather conditions. They conduct heat well and resist rust naturally, which makes them great for heavy duty work, vehicles that rack up lots of miles, or older cars that still hit the road daily despite their extra weight. Aluminum options respond quickly to temperature changes and save quite a bit of weight, but they don't hold up as well over time when exposed to constant heating and cooling cycles or harsh coolants. Most last between six and eight years before showing signs of wear like pits forming or joints weakening. There are also plastic aluminum hybrid models available at lower prices that weigh even less, though these can be problematic at the point where the tank meets the core. Different rates of expansion between materials there often lead to unexpected leaks within five to seven years of operation. If getting the longest possible life out of a radiator is important, go with copper brass for tough situations. Pick aluminum when saving weight and improving fuel efficiency matter more, especially if regular servicing isn't too much of a hassle. Save the hybrid models for cases where money is tight and usage isn't too intense, since people who buy these usually plan on replacing them sooner rather than later anyway.

FAQ Section

What are the benefits of copper-brass car radiators?

Copper-brass car radiators are excellent at conducting heat, which helps cool engines quickly and efficiently. They also resist corrosion effectively, have a longer service life, and are less prone to electrolytic damage compared to other radiator materials.

Why are aluminum radiators prone to corrosion?

Aluminum radiators can experience galvanic corrosion, especially when exposed to different metals and harsh environmental conditions. They fail to form a protective oxide layer and are sensitive to corrosive elements in coolants.

What are the drawbacks of plastic-aluminum hybrid radiators?

Plastic-aluminum hybrid radiators often suffer from structural integrity issues at the tank-to-core interface due to mismatched expansion rates of materials. This can lead to unexpected leaks after a few years of use.

Which car radiator material is best for long-term durability?

Copper-brass radiators offer the best long-term durability and lifespan, typically lasting 12 to 15 years under normal driving conditions, making them suitable for heavy-duty applications and vehicles that accumulate high mileage.

Table of Contents

- Copper-Brass Car Radiators: Proven Longevity and Thermal Performance

- Aluminum Car Radiators: Lightweight Efficiency vs. Long-Term Durability Trade-Offs

- Plastic-Aluminum Hybrid Car Radiators: Cost Savings at the Expense of Structural Integrity

- Comparing Car Radiator Materials: A Practical Guide to Choosing for Maximum Lifespan

- FAQ Section