Why Oil Filter Efficiency Is Critical for Modern Engine Performance

Engines these days run at really high pressures and temperatures, so even tiny bits of dirt can cause big problems over time. When the oil filter isn't doing its job properly, those little abrasive particles around 10 to 20 microns in size keep moving through the engine, basically scratching up the bearings, cylinder walls, and camshafts as they go. The result? A much shorter life for the engine. According to some industry research from Machinery Lubrication back in 2022, about three quarters of early engine wear comes down to these tiny particles getting in there. And it's not just about parts wearing out. If filters get blocked or aren't efficient enough, the oil flow gets restricted, which makes the engine strain more than it should. This extra effort means using more fuel too something like 2% more in some cases and also cuts down on how much power the engine can actually produce.

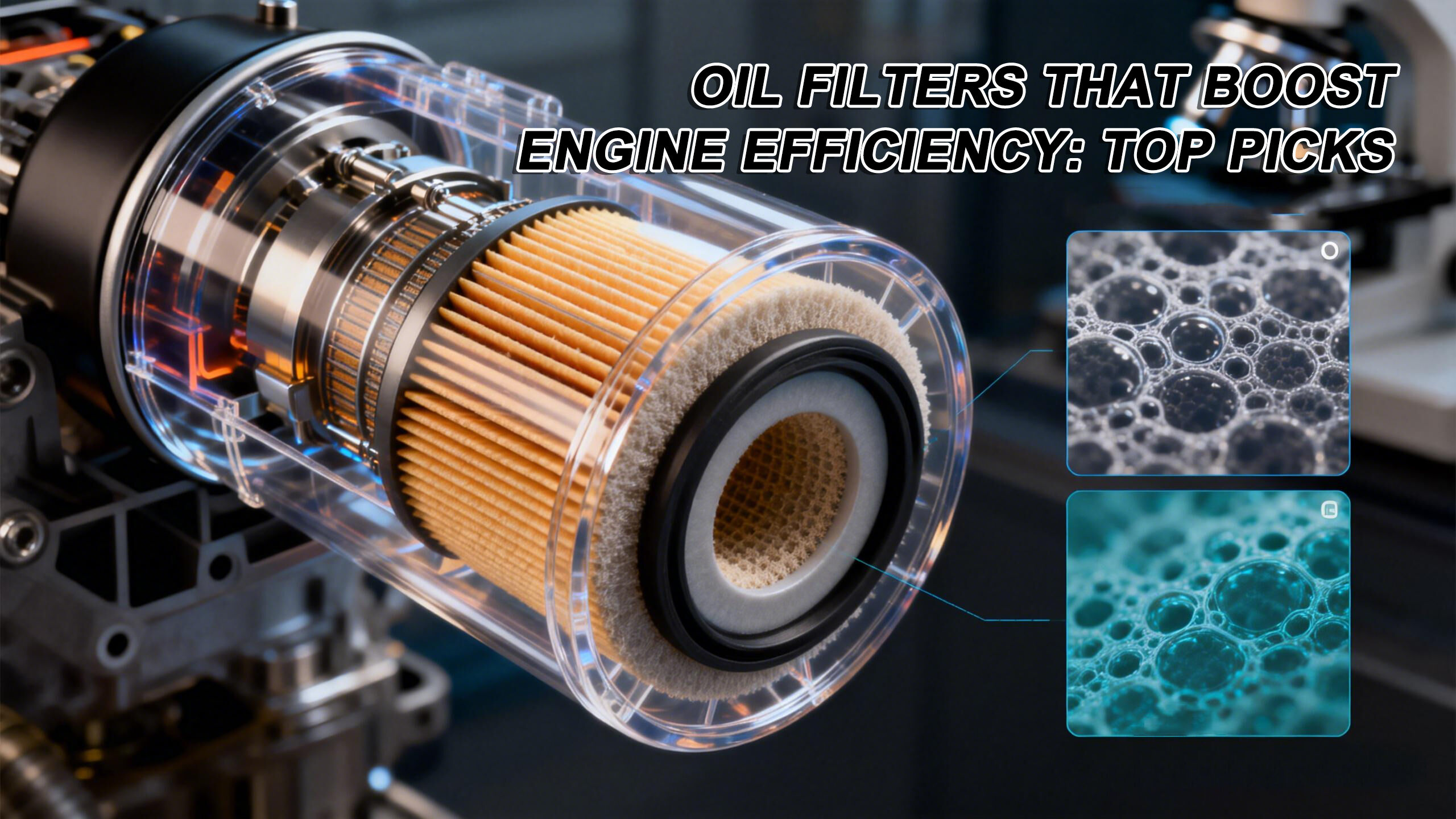

The best oil filters fight off these problems using special materials and careful design work, trapping about 99 percent of dirt particles down to very small sizes. When the oil stays clean, it keeps flowing properly so important parts like turbochargers and those fancy variable valve timing systems get what they need. These components are super picky about how clean their oil is. Keeping things running smoothly helps save gas money too, while avoiding situations where engines run low on oil when spinning really fast. If we ignore good filtration, the oil gets dirty quicker and won't last as long between changes. Modern cars have much tighter spaces inside their engines compared to older models. So picking the right oil filter goes beyond regular maintenance now days. It actually acts as protection from expensive fixes later on. We're talking serious cash here folks - major engine work can set someone back around four grand according to recent data from Car Care Council.

Key Oil Filter Efficiency Metrics: Micron Rating, Beta Ratio, and Real-World Filtration Performance

Understanding beta ratio testing and how it quantifies oil filter efficiency

The beta ratio, often written as β, serves as the standard measure for how well filters actually work. Basically, it looks at how many particles are present before and after they go through the filter at certain sizes. The calculation goes something like β equals particles greater than or equal to x microns upstream divided by those same sized particles downstream. From this number we calculate efficiency percentage with the formula (1 minus 1 over β) multiplied by 100. Take β at 200 for instance, which means the filter catches 99.5% of all 5-micron particles. These tiny bits cause most engine damage over time. Today's top quality filters can hit β = 1000 ratings (that's 99.9% efficiency) thanks to better materials and design. Standard pass/fail testing just doesn't cut it anymore. Instead, manufacturers rely on multipass beta testing following SAE J1858 guidelines. This method checks how filters perform continuously when exposed to ongoing contamination, much closer to what happens in real engines during normal operation.

Nominal vs. absolute micron ratings – what they reveal (and hide) about oil filter performance

Micron ratings require careful interpretation:

- Absolute micron rating specifies the largest particle guaranteed not to pass through the media (e.g., “10 microns absolute� means zero particles larger than 10 μm exit the filter).

- Nominal micron rating indicates only approximate capture efficiency–often between 50–90% at that size–and offers no performance guarantee.

The difference really matters. Filters labeled as nominal 10 microns might let through around 40% of those pesky 15 micron metal bits during cold engine starts. That's when the oil gets thickest and dirt gets in easiest. Absolute rated filters work better consistently no matter what temperatures or loads we throw at them. Most companies love talking up their nominal ratings because they sound good on spec sheets. But actual tests tell another story these filters efficiency drops or jumps over 30% depending on how things run. So for today's engines that need precision, looking at verified beta ratios or absolute ratings makes much more sense than trusting just any old marketing number.

Filter Media Types Compared: Cellulose, Synthetic Blend, and Full-Synthetic Oil Filters

How media composition affects oil flow, dirt-holding capacity, and engine protection

The makeup of oil filter media really affects how well filters perform across three main areas: keeping oil flowing smoothly, trapping contaminants, and protecting engines over time. Paper filters made from cellulose might be cheaper upfront but tend to have uneven fibers throughout, which causes problems like restricted flow and higher pressure drops early on. Once these paper filters get too full, they often force the system into bypass mode, letting dirty oil circulate through the engine instead of being filtered properly. Synthetic materials tell a different story though. They maintain consistent pores throughout, allowing around 17% better oil flow even when dealing with similar amounts of dirt according to Machinery Lubrication Analysis from last year. When it comes to holding onto dirt, top quality synthetic filters can trap nearly 2.5 times as much debris before needing replacement compared to regular paper ones, which makes all the difference for longer service intervals especially in tough driving conditions. The durability factor matters too. Regular paper filters break down quickly when faced with acidic stuff from combustion or oil mixed with fuel, whereas synthetic polymers hold up much better against chemicals. Real world testing indicates that engines equipped with full synthetic filters show about 60% less wear on bearings after covering 50 thousand miles, something that translates directly into fewer repairs and longer engine life for most drivers.

| Media Type | Oil Flow Stability | Avg. Dirt Capacity (grams) | Chemical Resistance |

|---|---|---|---|

| Cellulose | Moderate decline | 12–15g | Low |

| Synthetic Blend | Gradual decline | 18–22g | Moderate |

| Full-Synthetic | <10% variance | 28–33g | High |

Synthetic blends work pretty well for regular driving around town most days. But when it comes to those high performance cars, turbocharged models, or vehicles stuck in traffic all day long, full synthetic oil really shines. Modern engines today often run on these thinner synthetic oils, and this matters because good quality filter media stops fibers from breaking off inside the engine. We've seen problems before where old style filters made with cellulose start shedding bits that get stuck in small oil channels. These blockages can cause serious issues in systems like variable valve timing components or the feed lines going to turbochargers.

FAQ

What is the significance of oil filter efficiency in engine performance?

Oil filter efficiency is crucial for engine performance because it prevents tiny abrasive particles from causing wear and tear inside the engine. Efficient filters keep the engine running smoothly, enhance fuel efficiency, and prolong the engine's lifespan.

How does the beta ratio relate to oil filter efficiency?

The beta ratio measures a filter's performance by comparing particle counts upstream and downstream of the filter. A higher beta ratio indicates better efficiency in removing particles.

What is the difference between nominal and absolute micron ratings?

Absolute micron rating guarantees the largest particle size that will not pass through the filter. Nominal micron rating indicates an approximate capture efficiency and does not offer performance guarantees.

Why are synthetic oil filters recommended for modern engines?

Synthetic oil filters are recommended for modern engines because they offer consistent flow, high dirt-holding capacity, and resistance to chemical degradation, resulting in better engine protection and longer service intervals.